Process

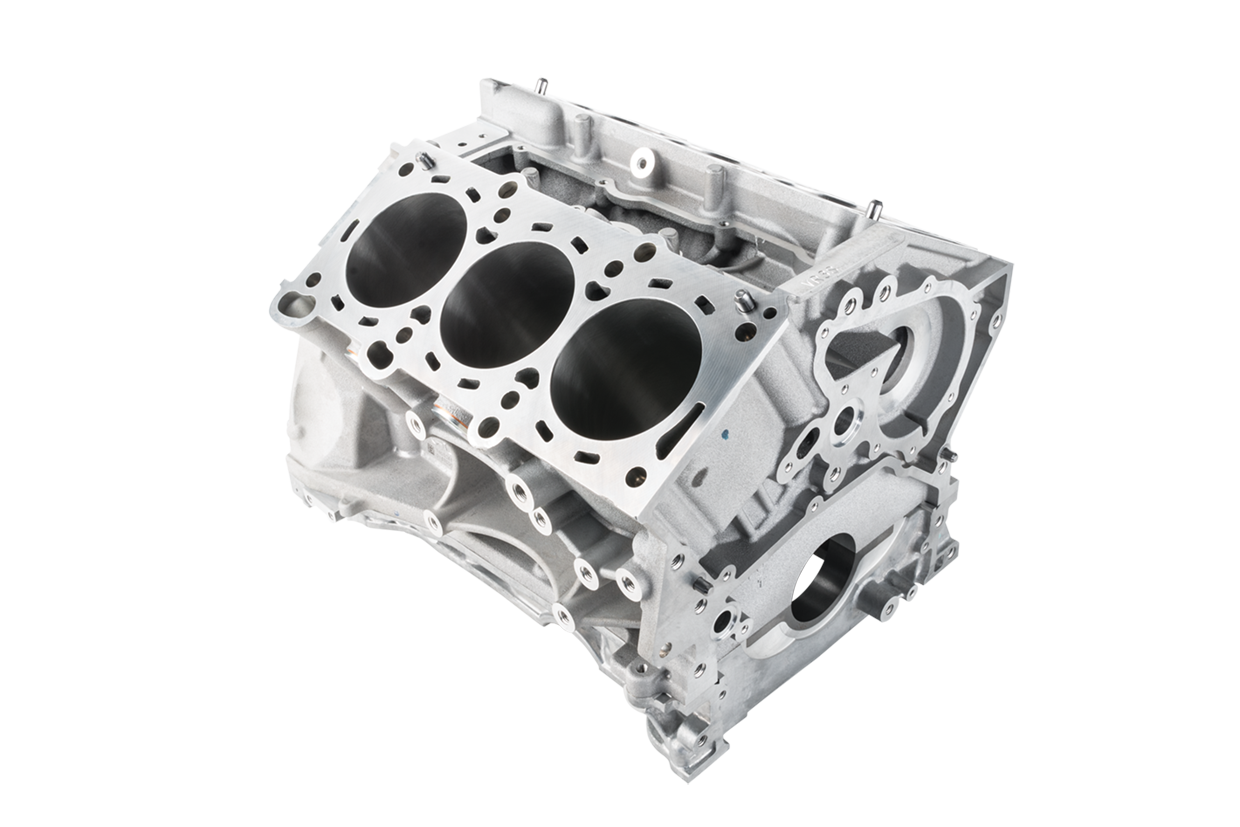

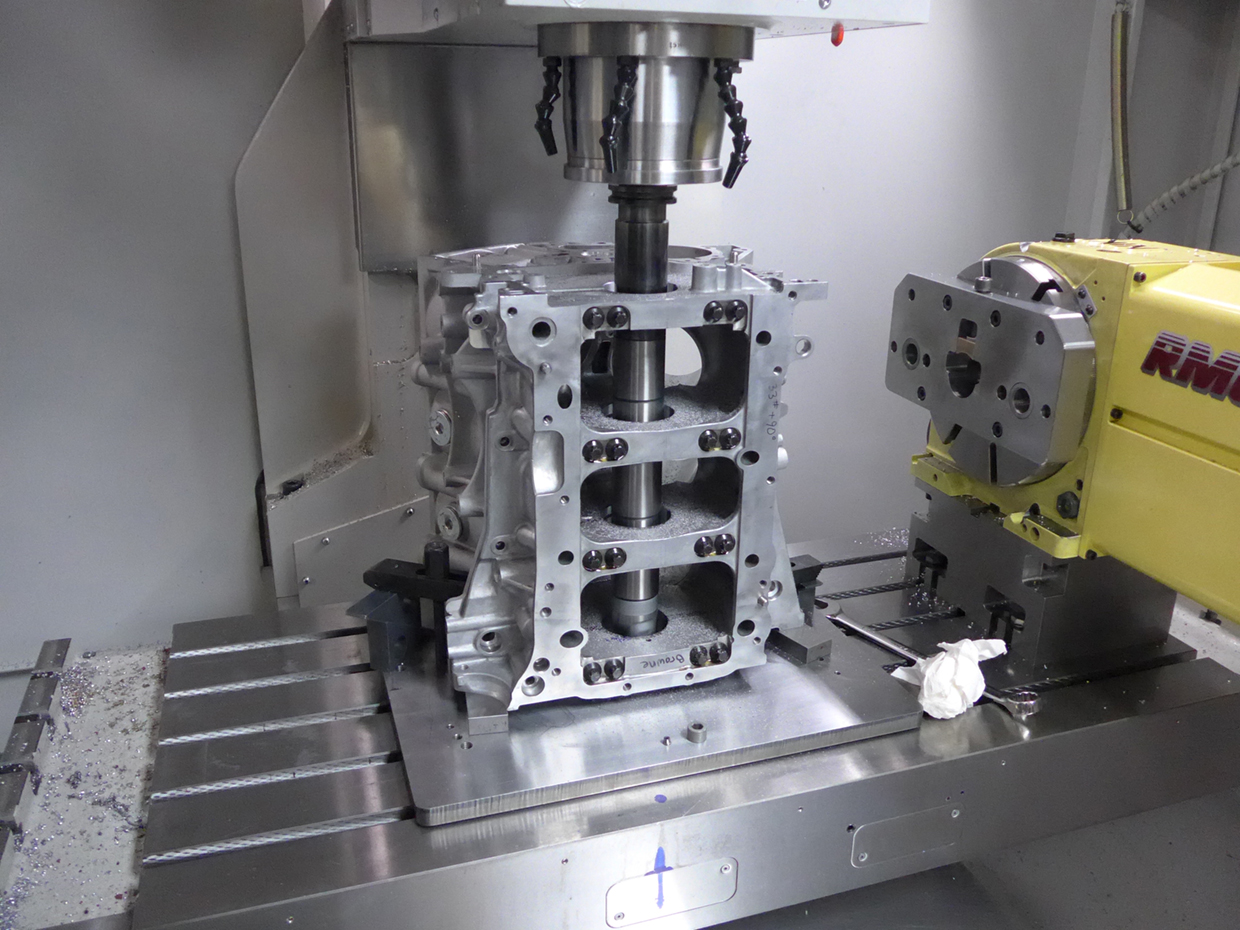

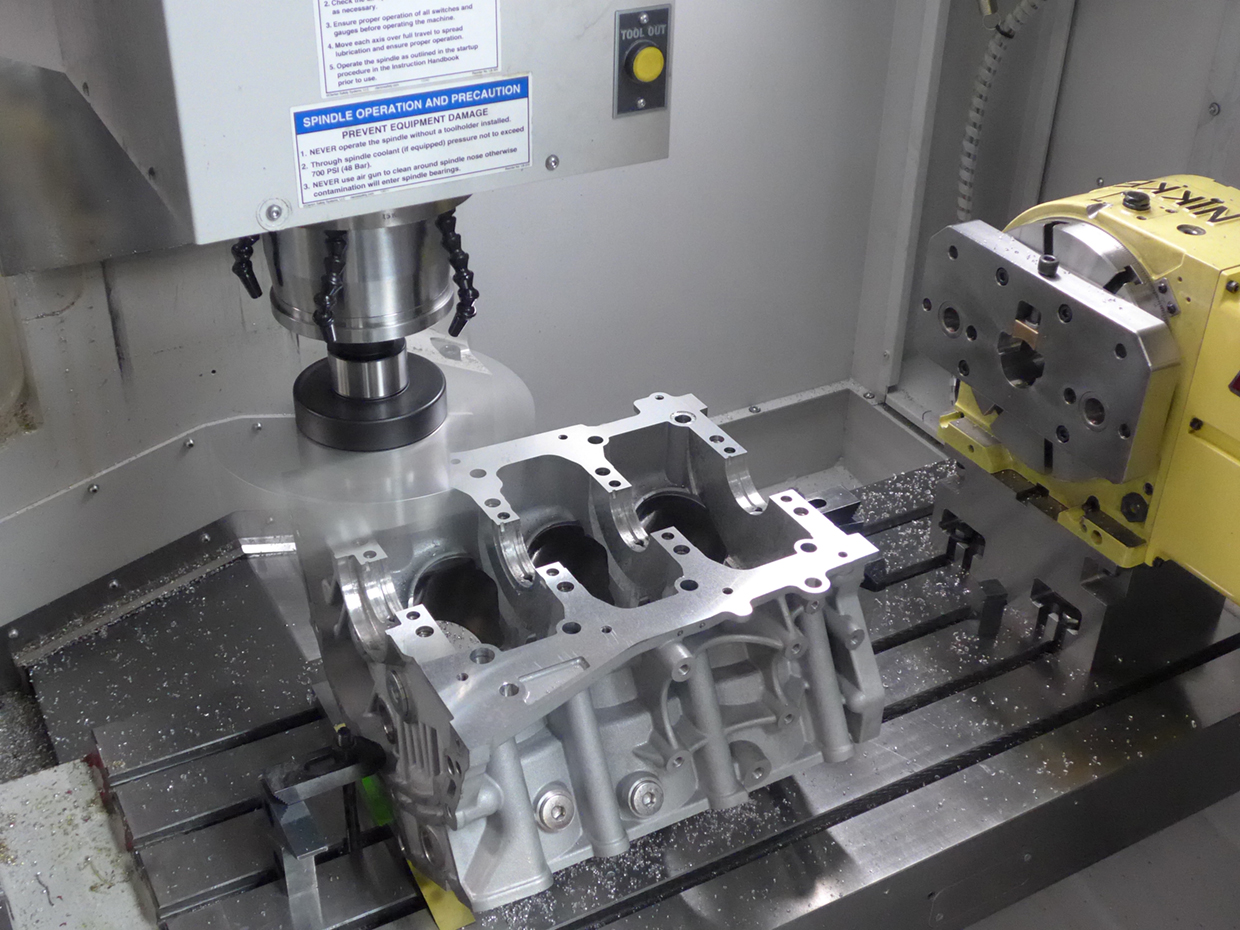

Machining

- CNC line boring of engine block’s main journals

- CNC decking of engine to match deck heights between banks

- CNC decking of engine for Ra<15 for optimal MLS gasket sealing surface

- Precision honing of connecting rod small end where needed

- Precision honing of connecting rod big end where needed

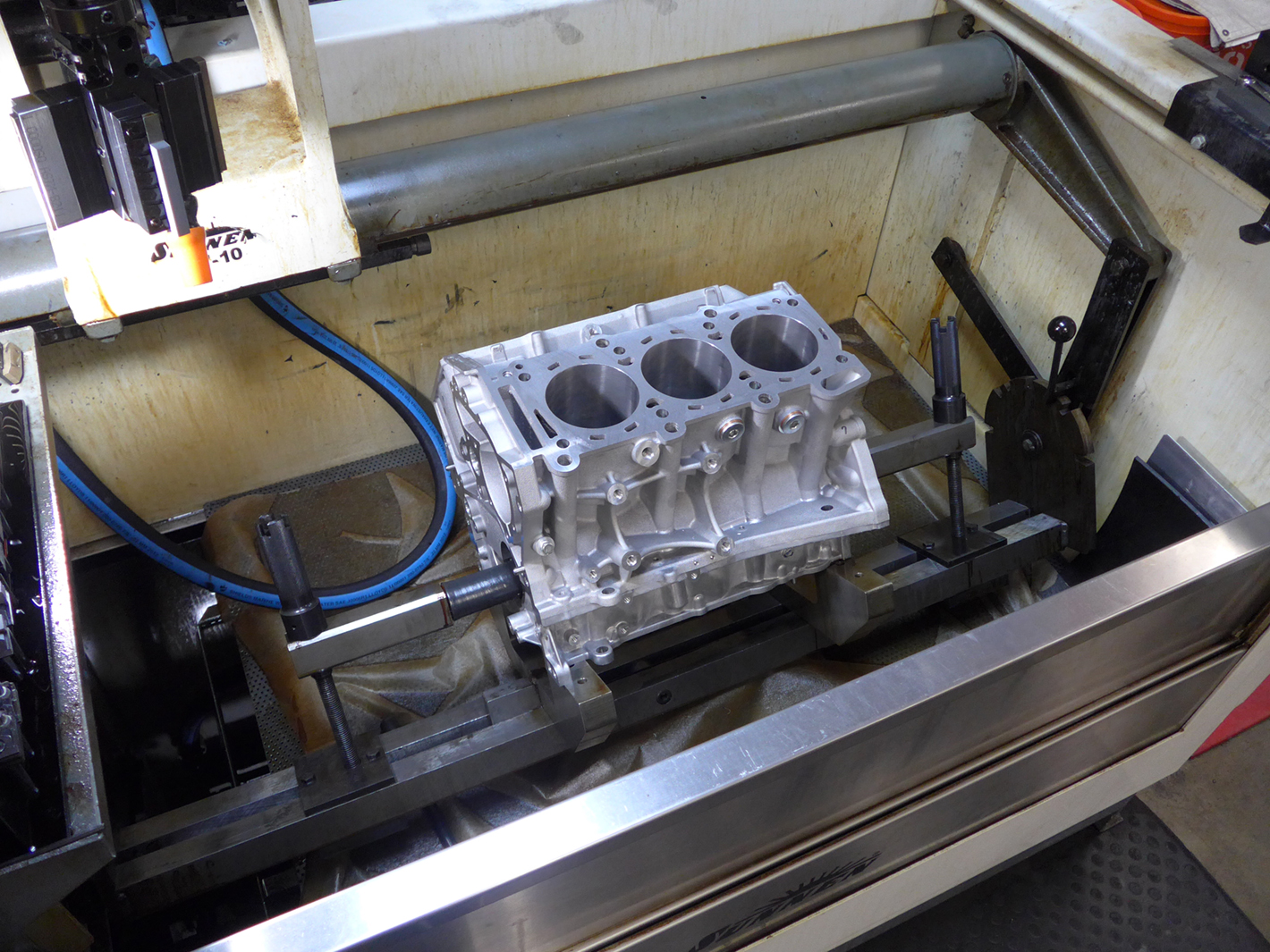

- Precision diamond plateau honing of all cylinders with DSPORT Torque Plate*

- Surface finish matching of all cylinders to ideal finish measured with profilometer

- Micropolishing of all crankshaft journal surfaces

- Deburring of ring end gaps following filing

- Deburring of piston crowns, valve reliefs and skirt edges

Balancing

- Match balance of all pistons and pins to within +/- 0.2grams

- Match balance of all connecting rod small ends to within +/- 0.2grams

- Match balance of all connecting rod big ends to within +/- 0.2grams

- Dynamic balance of crankshaft to less than 0.25grams

- Dynamic balance of flywheel to less than 0.25grams

- Measure of dynamic torque for rotation of rotating assembly

Assembly

- Installation of graded main bearings in block for ideal main oil clearances

- Installation of graded rod bearings in rods for ideal rod oil clearances

- Installation of crankshaft and angle torque of main studs in block

- Measurement of all rod and main pins on crankshaft

- Measurement of crankshaft end play and thrust adjustment where needed

- Measurement of piston pin-to-piston and piston pin-to-rod small end

- Rod side clearance measured and adjusted when Necessary

- Piston/rod assemblies installed with indexed ring end gaps

- All rod bolts torqued to bolt manufacturer’s stretch recommendation

Cleaning

- Automated Ultrasonic and Jet Washing Operations

- Hand brush wash of all components at multiple stages

*This torque plate was engineered and developed to exactly match distortion of cylinders when cylinder heads are torqued into place with a factory head gasket and either factory head bolts or ARP CA625+ head studs.